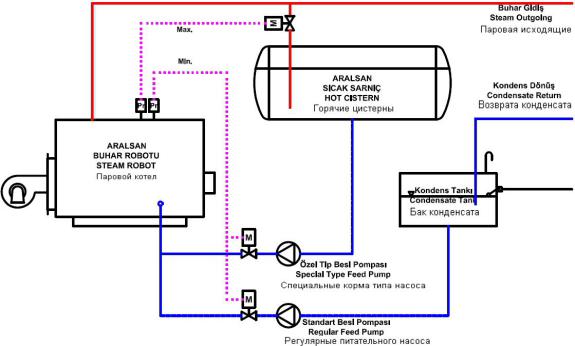

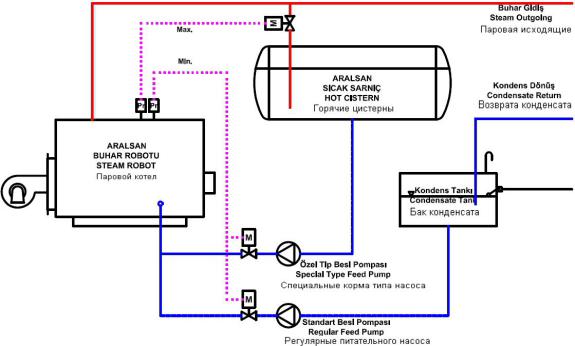

A pressurized feed water rezerv at saturation temperature is obtained by sending excess steam to a water storage tank (cistern) when steam consumtion in process drops if there is variable steam consumption in a process.

Special type cistern pump is automaticaly activated and feeds water to boiler from hot cistern when a pik steam demand occurs at process. Main feed pump is automatically disabled during this period. Water passes to steam phase very fast only by being given steaming heat because the water coming from cistern is at saturation temperature. So, an additional steam amoun can be withdrew from boiler by using hot cistern.

For more information you can read our article "HOT CISTERN" for usage of hot cistern. Unfortunatelly it is available only in Turkish for now.